Daily press, 2025-12-30, 10:58 am

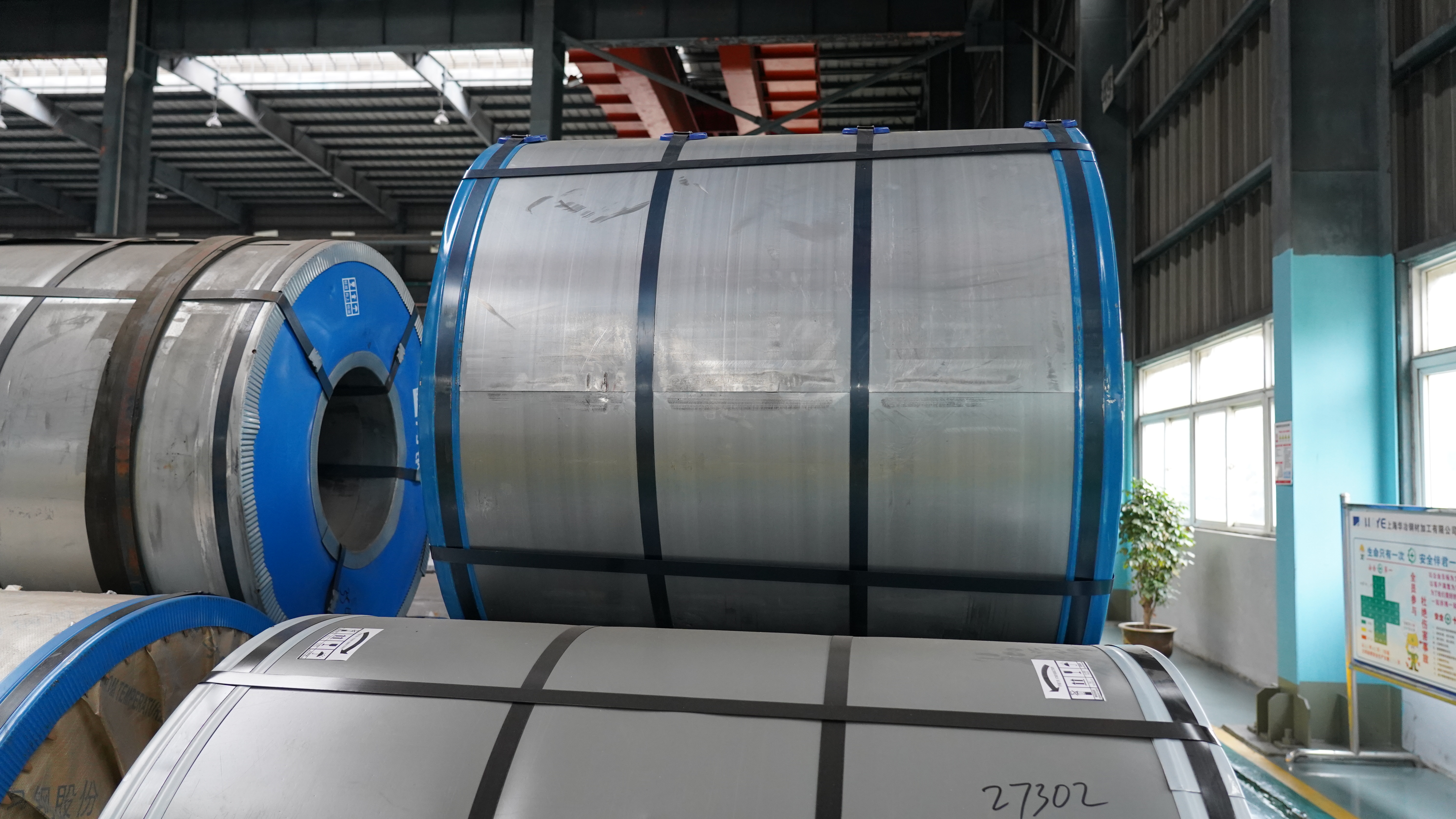

Analysis of the Process Core of Steel Plates and Galvanized Steel Plates

In the fields of industrial design and decorative engineering, the selection of steel plates and galvanized steel plates directly affects the durability and aesthetic effect of projects. As a practitioner deeply engaged in the field of metal surface treatment, I will start from the essence of the process and technical parameters, disassemble the core differences between the two, and clarify the underlying application logic.

I. Raw Steel Plates: The Basic Core of Industrial Applications

The core of ordinary steel plates is high-precision rolled carbon steel, and their performance is jointly determined by the base material composition and processing technology:

Cold-rolled steel plates: Surface roughness Ra ≤ 1.6μm, tensile strength ≥ 270MPa, suitable for precision stampings;

Hot-rolled steel plates: Thickness tolerance ±0.15mm, yield strength ≥ 235MPa, commonly used in building load-bearing structures.

The fatal shortcoming of raw steel plates is their susceptibility to oxidation and rusting—in an environment with 60% humidity, initial rust spots on bare carbon steel can appear in only 72 hours.

II. Galvanizing Process: Dual Protective Upgrade for Steel Plates

Electrogalvanizing (SECC)

Process core: Depositing a zinc layer (5-30μm) through electrolysis, surface hardness HV80-120; steel plates with this process are suitable for automotive interior sheet metal parts and high-end home appliance casings;

Hidden requirements: Zinc consumption is about 15g per square meter, and the content of trivalent chromium in the passivation solution must be strictly controlled.

Hot-dip Galvanizing (SGCC)

Metallurgical principle: Forming an FeZn alloy layer (30-275μm) in a zinc bath at 440℃, salt spray test life ≥ 500 hours;

Cost advantage: The cost of large-scale production is 60% of that of electrogalvanizing, suitable for photovoltaic brackets and traffic guardrails.

III. Selection Guide

1. Corrosion resistance comparison: Electrogalvanizing can withstand C2 and C3 grade environments (72-240 hours); hot-dip galvanizing can cover harsh C4 and C5 grades (500-1000 hours);

2. Processing adaptability: Electrogalvanized steel plates have an elongation rate ≥ 18%, suitable for deep stamping processing; hot-dip galvanized steel plates require argon protection during welding to avoid zinc layer damage;

3. Full-life cycle cost model: Electrogalvanizing has a low initial purchase cost but requires regular maintenance; hot-dip galvanizing can achieve 50-year maintenance-free operation, reducing the total cost by 40%; optimizing the rolling pass can further reduce the cost by 12.8%.

IV. Artistic Applications of Galvanized Steel Plates

In the field of high-end decoration, galvanized steel plates have long exceeded their material properties and become a carrier for artistic creation:

Etched relief: Using laser ablation technology to create 0.1mm-level three-dimensional textures;

Anodization: Generating nano-level iridescent gradient films;

Zinc layer translucency: Precisely controlling the crystallization rate to form unique snowflake-like zinc flower textures.

Choosing between steel plates and galvanized steel plates essentially means finding a balance between material performance and creative possibilities. When the rigor of industrial parameters meets the intuition of artistic creation, metal plates are endowed with a second life—which is the ultimate charm of modern industrial aesthetics.

Related Reading

Other News

Contact and Support

Ilin Ye

Steel Business Manager

5F, Building 7, No. 7 Youyi Road,

Baoshan District,

Shanghai, China.

Baoshan District,

Shanghai, China.

t/f: +86 (0)21 56162819

m: +86 15618590326

Further questions?

Please feel free to contact us for more information or enquiries.