+86(21)56162819[email protected]

- Home

- Services

-

Steel Products

- Hot rolled coil

- Cold rolling

- Precision steel belt

-

Plate

- Energy use steel plate

- Atmospheric corrosion resistant steel plate

- Offshore platform steel plate

- Low temperature pressure vessel steel plate

- High strength and toughness container steel plate

- Boiler vessel plate

- Bridge slab

- Building structural steel plate

- Low alloy structural steel plate

- High strength ship plate

- High strength steel plate

- Wear-resistant steel plate

- Alloy steel plate

- Pickling steel coil

- Silicon Steel

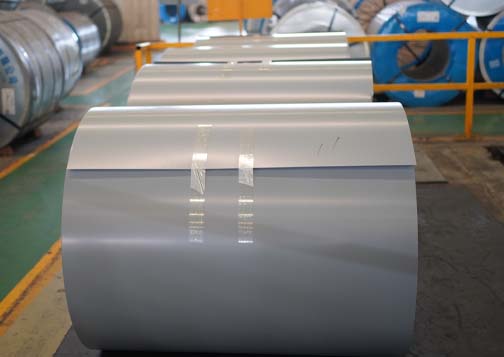

- Coating

- Stainless steel

- Nickel-based alloy

- Mould steel

- Round bar steel

- Steel tube

- OEM

- News

- About