Daily press, 2025-12-25, 02:35 pm

AHSS Generations & Traditional Steel: Features Comparison

Steel is a core basic material for the automotive industry and manufacturing. Based on microstructure characteristics, strengthening mechanisms and performance features, it can be categorized into traditional steel and three generations of advanced high-strength steel (AHSS). Different grades achieve a balance of strength, ductility and cost through differentiated chemical composition design and processing technologies, meeting diverse industrial application requirements.

Traditional steel grades including Mild Steel, Bake-Hardening Steel (BH), Carbon-Manganese Steel (CMn), Interstitial-Free Steel (IF/IF-HS) and High-Strength Low-Alloy Steel (HSLA) are matrixed on ferrite microstructure, with strengthening methods including solid solution strengthening, precipitation strengthening and grain refinement. Benefiting from diversified performance, excellent formability and a mature supply chain, they are widely used in the automotive and various manufacturing sectors.

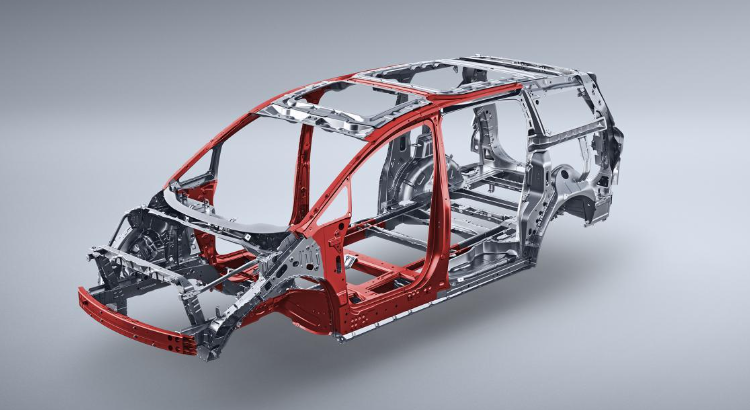

First-generation AHSS comprises Dual-Phase Steel (DP), Ferrite-Bainite Steel (FB), Press-Quenched Steel (PQS/PHS), Transformation-Induced Plasticity Steel (TRIP), Complex-Phase Steel (CP) and Martensitic Steel (MS). It enhances strength through microstructure strengthening and phase transformation strengthening, with a microstructure of ferrite matrix plus low-temperature transformation products. Among them, Press-Quenched Steel (PHS) attracts considerable market attention due to its advanced manufacturing process and outstanding performance.

Second-generation AHSS features a full austenitic microstructure, with representative grades such as Austenitic Stainless Steel and Twinning-Induced Plasticity Steel (TWIP). It exhibits an excellent strength-ductility balance. However, the need for large amounts of alloying elements leads to high costs, low yield strength and poor processability, driving the research and development of third-generation AHSS.

Through innovative microstructure design, third-generation AHSS incorporates stabilized austenite into the matrix of ultrafine-grained ferrite, bainite or martensite, achieving simultaneous improvement of strength and ductility at low cost. Major grades include Dual-Phase Steel (DH), Complex-Phase Steel (CH), Transformation-Induced Bainitic-Ferrite Steel (TBF), Carbide-Free Bainite Steel (CFB), Quenching and Partitioning Steel (QP) and Medium-Manganese Steel (MedMn). Specifically, QP steel and TBF steel enhance ductility via retained austenite phase transformation, while MedMn steel optimizes performance through the alloying effect of manganese.

-

First-generation AHSS: Highest strength, poorest ductility

-

Second-generation AHSS: Moderate strength, excellent ductility, high cost

-

Third-generation AHSS: Excellent strength-ductility balance, low cost, suitable for automotive chassis components

-

Traditional steel: Mature manufacturing process, high cost-effectiveness, applicable to general-purpose components

Related Reading