A while ago, we received an inquiry and quotation request from a customer regarding 304L stainless steel strips. From the very beginning, the customer clearly focused on the material's corrosion resistance, processing precision, and environmental compliance. We immediately provided detailed unit prices for different thicknesses (0.3-2.0mm) and widths (20-300mm), along with material certificates for 304L (including test reports on low carbon content ≤0.03% and chromium-nickel ratio). We also patiently answered the customer's core questions about welding performance and intergranular corrosion resistance. However, the customer stated that they needed to compare with multiple suppliers and then there was no further feedback for a while. They remained hesitant and delayed placing the order.

Half a month later, the customer finally took the initiative to contact us and completed the order placement. It was learned that during this period, the customer had consulted five peer companies one after another, and made a detailed comparison in terms of material stability, production process, past cooperation cases, and after-sales support. Eventually, they decided to cooperate with our company due to our complete qualification certifications (ISO9001 Quality Management System, SGS Environmental Test Report), clear process descriptions, and transparent quotation system.

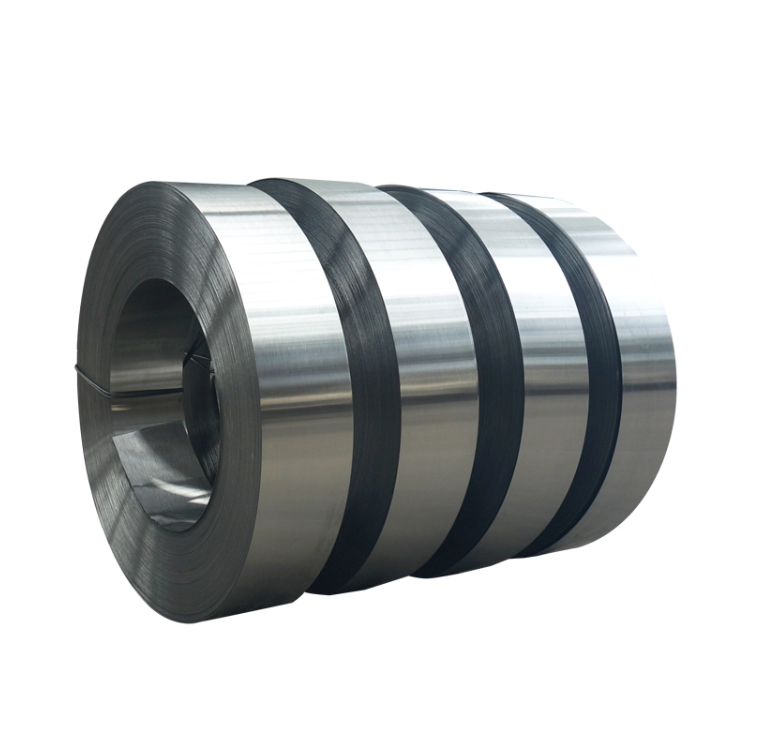

We highly value the customer's trust and are grateful for their recognition of our quality. After in-depth communication with the customer, we clarified the specific requirements for the 304L stainless steel strips: thickness of 0.8mm, width of 150mm, surface finish reaching 2B cold-rolled precision, no burrs on the edges, and packaging using moisture-proof film + hard paper tube wrapping (to avoid scratches during transportation). A 30-day delivery cycle was also agreed upon. After the communication, we immediately initiated the production scheduling, prioritized the allocation of raw materials and equipment, and fully promoted the production of 304L stainless steel strips.

The customer purchased the 304L stainless steel strips to manufacture conveyor components for food processing machinery. Considering that the equipment would be in direct contact with food ingredients, there were extremely high requirements for the material's acid and alkali corrosion resistance and no heavy metal precipitation. The low-carbon characteristics and excellent corrosion resistance of 304L perfectly met this demand. Before production, we conducted strict pre-treatment on the raw materials: through solution heat treatment (heating at a high temperature of 1050°C followed by rapid cooling), we improved the material's toughness and processability, while removing the oxide scale on the surface of the raw materials to ensure subsequent rolling precision. During the processing, we adopted a precision cold-rolling process to control the thickness tolerance within ±0.02mm, and the edges were treated with numerical control cutting + polishing to ensure no burrs or sharp edges. In view of the characteristics of 304L being easy to process but requiring avoidance of overheating, we used a water-cooling system throughout the process to effectively control the rolling temperature, prevent oxidative discoloration on the material surface, and ensure surface smoothness.

During the production process, we established a multi-link inspection mechanism: samples were taken from each batch for hardness testing (to ensure HRB ≤92) and corrosion resistance testing (48-hour salt spray test with no rust). We also monitored the dimensional accuracy and surface quality in real time, and adjusted process parameters in a timely manner when problems were found to ensure stable production quality.

In the end, our 304L stainless steel strip products were completed 3 days ahead of the agreed delivery period. After completing the moisture-proof packaging as required by the customer and attaching the complete test report, the products were successfully delivered to the customer's factory via dedicated logistics. Upon receiving the goods, the customer immediately conducted sampling inspection and trial processing. They reported that the dimensional accuracy and surface smoothness of the material fully met expectations, no intergranular corrosion occurred after welding, and it completely satisfied the usage requirements of food processing machinery. The customer highly recognized our product quality and delivery efficiency.

Baoshan District,

Shanghai, China.