Daily press, 2025-11-12, 03:03 pm

What is stainless steel? What are the classifications of stainless steel?

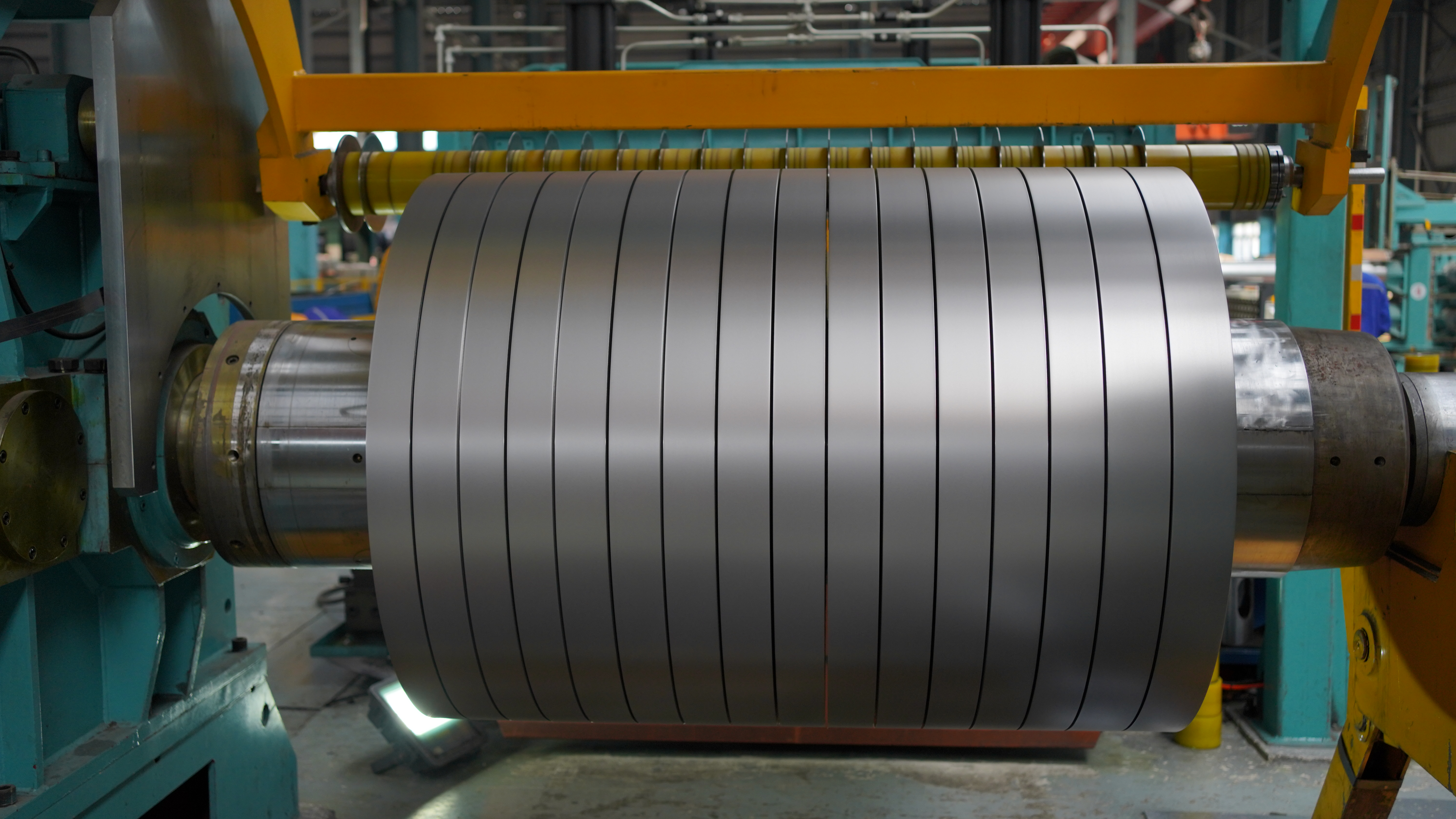

Stainless Steel: Material Characteristics, Core Advantages, Application Scenarios and Typical Grades

As an indispensable key material in the modern industrial system, stainless steel is widely used in numerous fields such as machinery manufacturing, construction engineering, medical equipment, and aerospace, thanks to its excellent corrosion resistance, high-strength mechanical properties, and good processing adaptability. It plays an important supporting role in promoting the high-quality development of various industries. Below is a systematic analysis of five types of stainless steel from three dimensions: material characteristics, core advantages, and application scenarios, supplemented by typical grade representatives (ASTM/EN/DIN EN/JIS).

Austenitic stainless steel uses chromium and nickel as the main alloying elements, presenting a single-phase austenitic structure at room temperature. It boasts outstanding strength and toughness, uniform corrosion resistance, and good cold working performance. Meanwhile, it maintains stable mechanical properties in low-temperature environments without cold brittleness. With strong processing adaptability, it can realize various processing technologies such as stamping, welding, and forging. Its surface is easy to polish, achieving high surface finish. Widely applied in industrial and civil fields, it is the preferred material for manufacturing food processing equipment, kitchenware, medical devices (e.g., surgical instruments, disinfection equipment), chemical pipelines and pressure vessels, and building decoration components in coastal areas. It is also extensively used in the production of low-temperature components in the aerospace field.

Typical grade representatives:

-

ASTM : 304, 316, 321

-

EN /DIN EN: X5CrNi18-10, X5CrNiMo17-12-2, X6CrNiTi18-10

-

JIS : SUS304, SUS316, SUS321

Ferritic stainless steel mainly contains chromium (chromium content usually ranges from 11% to 30%), with a ferrite structure as the main phase at room temperature. It has excellent oxidation resistance, especially prominent corrosion resistance to oxidizing media (e.g., air, water vapor) in high-temperature environments. It also possesses good stress corrosion cracking resistance and pitting corrosion resistance. This type of stainless steel has a small coefficient of thermal expansion, better thermal conductivity than austenitic stainless steel, and no nickel element, resulting in relatively low material cost. In the construction field, it is often used to make curtain wall decorative panels, roof drainage systems, and steel structural parts. In the chemical industry, it is suitable for manufacturing nitric acid production equipment, organic acid treatment devices, and heat exchangers. Additionally, it is widely used in automotive exhaust systems and household appliances (e.g., washing machine inner tubs).

Typical grade representatives:

-

ASTM : 430, 409L, 444

-

EN /DIN EN : X6Cr17, X2CrTi12, X2CrMoTi18-2

-

JIS : SUS430, SUS409L, SUS444

Martensitic stainless steel has a high chromium content (usually 12% to 18%) and a certain amount of carbon. After quenching and tempering, it can form a martensitic structure, featuring high strength, high hardness, and excellent wear resistance, along with certain corrosion resistance (mainly for neutral media such as the atmosphere and fresh water). Its mechanical properties can be adjusted by modifying heat treatment processes to meet the differentiated requirements for material strength and hardness in different scenarios. In the machinery manufacturing field, it is an ideal material for producing high-strength and wear-resistant components such as cutting tools, molds, bearings, gears, and valve cores. In the petroleum and chemical industry, it is suitable for manufacturing wellhead devices, drill pipe joints, and other components that withstand high pressure and wear. It is also used in the production of precision and wear-resistant products such as surgical scalpels and dental tools in medical devices.

Typical grade representatives:

-

ASTM : 410, 420, 440C

-

EN/DIN EN : X12Cr13, X20Cr13, X105CrMo17

-

JIS : SUS410, SUS420, SUS440C

Duplex stainless steel consists of a balanced two-phase structure of austenite and ferrite. It combines the excellent corrosion resistance, toughness, and processing performance of austenitic stainless steel with the high strength and stress corrosion cracking resistance of ferritic stainless steel. It also has better pitting corrosion resistance, crevice corrosion resistance, and higher fatigue strength than single-phase stainless steel. Its yield strength is much higher than that of austenitic stainless steel. Under the same stress requirements, it can reduce material thickness, lowering structural weight and manufacturing costs. In the oil and gas field, it is widely used in pipelines, wellhead equipment, and subsea oil pipelines of offshore oil and gas drilling platforms. In the chemical industry, it is suitable for manufacturing reaction equipment and heat exchangers for highly corrosive media such as sulfuric acid and phosphoric acid. In the water treatment field, it is used in seawater desalination plants and sewage treatment equipment. It is also gradually applied in heavy-load bearing scenarios such as bridges and high-rise building steel structures.

Typical grade representatives:

-

ASTM : 2205, 2507, 2304

-

EN /DIN EN : X2CrNiMoN22-5-3, X2CrNiMoN25-7-4, X2CrNiN23-4

-

JIS : SUS2205, SUS2507, SUS2304

Precipitation hardening stainless steel is based on martensitic or austenitic stainless steel, with the addition of alloying elements such as copper, aluminum, titanium, and niobium. After solution treatment and aging treatment, the alloying elements precipitate in the form of intermetallic compounds to achieve material strengthening. It has ultra-high strength, high hardness, and good corrosion resistance, while maintaining stable mechanical properties in high-temperature environments. Its toughness is superior to ordinary martensitic stainless steel. With low density and a high strength-to-weight ratio, it is a typical high-strength and lightweight material. In the aerospace field, it is used to manufacture key load-bearing structural components such as aircraft landing gear, engine parts, and missile casings. In the nuclear industry, it is suitable for producing radiation-resistant and high-strength components such as fuel claddings and control rod drive mechanisms in nuclear reactors. It is also used in high-end medical devices (e.g., artificial joints) and precision instrument components that have extremely high requirements for material performance.

Typical grade representatives:

-

ASTM : 17-4PH, 15-5PH, PH13-8Mo

-

EN /DIN EN : X5CrNiCuNb16-4, X5CrNiCuNb15-5, X2CrNiMoAl13-8-2

-

JIS : SUS630, SUS631, SUS632

Related Reading