In modern automobile manufacturing and mechanical engineering, the selection of materials is crucial for the performance and safety of products. SAE J1392 060XLF and QStE380TM are two high-strength low-alloy steels widely used in the manufacture of high-strength structural components. These two materials are often used interchangeably. Let’s analyze their interchangeability based on the chemical composition, mechanical properties, application fields, and practical application cases of both materials.

I.Material Properties Comparison

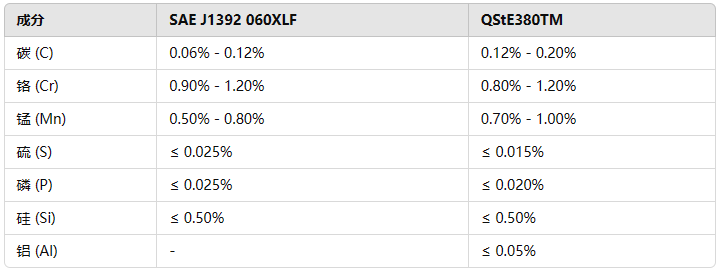

Chemical Composition

The main components of 060XLF include: Carbon (C): 0.06-0.12%, Chromium (Cr): 0.90-1.20%, Manganese (Mn): 0.50-0.80%, etc.

The main components of QStE380TM include: Carbon (C): 0.12-0.20%, Chromium (Cr): 0.80-1.20%, Manganese (Mn): 0.70-1.00%, etc.

Although there are certain differences in chemical composition, both have good weldability and formability, making them suitable for manufacturing automotive structural components.

Mechanical Properties

The tensile strength of 060XLF generally ranges from 380-450 MPa, and the yield strength is above 340 MPa.

The tensile strength of QStE380TM generally ranges from 380-490 MPa, with a yield strength between 340-380 MPa.

This indicates that the strength range of QStE380TM can cover that of 060XLF; thus, QStE380TM is an effective alternative in applications requiring high strength and toughness.

II.Application Fields

Automobile Manufacturing

Both materials are widely used in automobile manufacturing, especially in load-bearing structural components such as the body, chassis, and suspension systems. The performance of QStE380TM meets the stringent standards of the automotive industry, making it a viable choice when replacing 060XLF.

Mechanical Engineering

In mechanical engineering, both 060XLF and QStE380TM can be used to manufacture high-strength parts, such as gears, shafts, and other structural components. Their good weldability and formability make them suitable for complex shapes and high-load working conditions.

III.Practical Application Cases

Feedback from Automobile Manufacturers

Some automobile manufacturers have adopted QStE380TM as a substitute for 060XLF during production. Feedback indicates that using QStE380TM resulted in good performance in terms of strength and toughness, meeting production and safety requirements.

We have also received orders for QStE380TM steel for automotive parts from clients who used QStE380TM to replace 060XLF. After testing, they found that the tensile strength and fatigue life of the parts improved, and the production process was not adversely affected.

IV.Conclusion

In summary, the replacement of SAE J1392 060XLF with QStE380TM is feasible. Both materials show similarities in chemical composition, mechanical properties, and application fields. QStE380TM has performed excellently in many practical applications and can effectively replace 060XLF. For manufacturers looking to improve product performance or reduce costs, QStE380TM is a substitute worth considering. It is recommended to conduct necessary material performance tests during material replacement to ensure that specific application requirements are met.

Baoshan District,

Shanghai, China.