Daily press, 2025-09-26, 01:44 pm

Exploring the Chemical Composition and Application Landscape of Electrical Steel

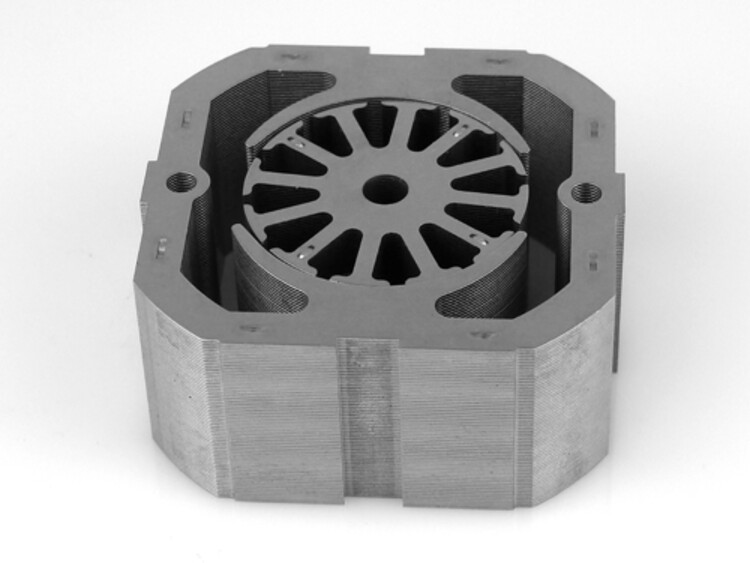

In the field of modern power industry and high-end manufacturing, electrical steel serves as a core foundational material for energy conversion. Its performance directly determines the energy efficiency and operational stability of key equipment such as transformers and motors, and it plays an irreplaceable supporting role in the development of strategic industries including new energy vehicles and clean energy power generation. With a long development history, electrical steel has undergone over a century of technological evolution, forming a systematic product category and technical standards. Currently, electrical steel is mainly divided into two major categories: non-oriented electrical steel sheets and grain-oriented electrical steel sheets. Due to differences in their performance characteristics, these two categories undertake important roles in different fields. This article will focus on the representative chemical composition of non-oriented electrical steel sheets, the mechanism of their impact on performance, and the general applications of the two types of electrical steel, providing a reference for understanding the technical characteristics and industrial applications of electrical steel.

1. Representative Chemical Composition of Electrical Steel

Electrical steel sheets are core materials for transformers and motors, and they are key materials for converting electrical energy into magnetic energy. With a long history, the development of electrical steel originated in 1900 when British scientist Hadfield discovered that adding silicon (Si) to iron could reduce iron loss—hence, electrical steel sheets are also known as silicon steel sheets. Electrical steel sheets are categorized into non-oriented and grain-oriented types. Below is a brief introduction to the composition, heat treatment, and technical trends of non-oriented electrical steel sheets.

1.1 Impact of Si and Al on the Performance of Non-Oriented Electrical Steel Sheets

Adding Si to steel can increase the steel's electrical resistance and reduce eddy currents generated during material magnetization. Therefore, a large amount of Si is usually added to electrical steel sheets. For example, the Si content of non-oriented electrical steel sheets used in drive motors of new energy vehicles is approximately 3%, while that of non-oriented electrical steel sheets for special applications can even reach 6.5%. In addition to Si, aluminum (Al) also has the effect of increasing electrical resistance. In high-grade electrical steel sheets, Al is added in combination with Si. The synergistic effect of these elements further optimizes the magnetic properties of the steel, making it easier to magnetize and thereby improving the energy conversion efficiency of equipment.

1.2 Impact of S, N, and O on the Performance of Non-Oriented Electrical Steel Sheets

In contrast to the positive effects of Si and Al, impurity elements such as sulfur (S), nitrogen (N), and oxygen (O) in steel have a significant negative impact on the performance of non-oriented electrical steel sheets. Specifically, S forms sulfides (e.g., MnS) in steel, N forms nitrides (e.g., AlN), and O forms oxides (e.g., SiO₂, Al₂O₃). These compounds form fine secondary phase particles inside the steel, which hinder the movement of magnetic domain walls and directly increase iron loss. Meanwhile, these fine sulfides and nitrides also inhibit the normal growth of grains, disrupt the uniformity of the steel's internal structure, and further exacerbate hysteresis loss. Therefore, during the production of non-oriented electrical steel sheets, refining processes and other methods must be used to minimize the content of impurity elements such as S, N, and O to ensure the magnetic performance indicators of the product.

1.3 Impact of Sn and Sb on the Performance of Electrical Steel Sheets

The magnetic properties of electrical steel sheets are closely related not only to their chemical composition but also to the arrangement of internal grains. Essentially, electrical steel sheets are aggregates of a large number of grains with a size ranging from tens of micrometers to hundreds of micrometers. When grains are arranged along a specific direction, the structure formed is called a textured structure—and a reasonable textured structure is key to improving the magnetic properties of the steel. Tin (Sn) and antimony (Sb) are typical grain boundary segregation elements. During the manufacturing process of electrical steel sheets, they selectively segregate at grain boundaries. By regulating the grain boundary energy and grain growth direction, they promote the development of textured structures that are beneficial for enhancing magnetic properties. Additionally, Sn and Sb also segregate on the surface of steel sheets, forming a protective segregation layer that effectively inhibits nitridation of the sheet surface during final annealing. This reduces the damage to magnetic properties caused by nitridation products, thereby lowering the iron loss of electrical steel sheets and improving the overall performance of the product.

2. Overview of General Applications of Electrical Steel

As mentioned earlier, electrical steel sheets are divided into non-oriented and grain-oriented types. Based on their different performance advantages, these two types have formed clear application divisions in the industrial field. The core characteristic of non-oriented electrical steel sheets is their low magnetic anisotropy—meaning there is little difference in magnetic properties in different directions of the steel. This feature makes them highly suitable for use as cores in motors and generators, which require multi-directional magnetic fields, as they ensure stable magnetic properties and low loss during the high-speed operation of equipment. In recent years, with the rapid expansion of the new energy vehicle industry and the popularization of clean energy equipment such as wind turbines and photovoltaic inverters, the market demand for non-oriented electrical steel sheets has shown a sharp growth trend, driving continuous upgrades in their production technology.

Grain-oriented electrical steel sheets, on the other hand, are known in the industry as "works of art among steels" due to the extreme difficulty in controlling their structure and the high precision requirements for production processes. Their most prominent performance advantage is their excellent magnetic properties in the rolling direction, featuring high magnetic permeability and extremely low iron loss. This characteristic makes them ideal core materials for transformers, as they can significantly improve the energy efficiency of transformers, reduce energy loss during power transmission, and are of great significance for building an efficient and energy-saving power system.

In summary, the chemical composition design of electrical steel is a core factor determining its magnetic properties. The scientific addition of Si and Al, the strict control of S, N, and O, and the precise regulation of textured structures by Sn and Sb together constitute the key technical path for optimizing the performance of non-oriented electrical steel sheets. Moreover, the differentiated applications of non-oriented and grain-oriented electrical steel sheets in fields such as motors, generators, and transformers—based on their respective performance characteristics—fully reflect the supporting role of electrical steel as a foundational material in industrial development. In the future, as high-end manufacturing imposes increasingly higher requirements on material performance, the optimization of electrical steel composition and innovation in manufacturing processes will continue to deepen, injecting stronger impetus into promoting efficient energy utilization and the development of green industries.

Related Reading