Cold-rolled thin steel sheets are indispensable basic materials in modern industry, widely used in numerous fields such as automobile manufacturing, home appliance production, and architectural decoration. Their excellent surface quality, high-precision dimensional control, and good mechanical properties are attributed to a rigorous and efficient production process. From raw material selection to finished product processing, precise control over every link directly affects the quality of the final product. The following will detailedly explain the production process of cold-rolled thin steel sheets and the development direction of this process in technological innovation.

I. Production Process of Cold-Rolled Thin Steel Sheets

The production of cold-rolled thin steel sheets involves a series of key steps, which together form a complete process flow. The details are as follows:

Raw Material Selection and Inspection: Hot-rolled strips with a thickness of 5 to 6 millimeters are used as the starting material for cold rolling. Before entering the cold rolling production line, these hot-rolled strips must undergo strict quality and dimensional inspections to ensure they meet the standards for cold rolling processing.

Pickling Process: The core purpose is to remove the scale and dirt on the surface of hot-rolled strips, providing a clean base material for subsequent cold rolling and surface treatment. Pickling usually uses acid solutions such as hydrochloric acid or sulfuric acid. After the strips are soaked and rinsed in the acid solution, the surface oxides can be completely removed. With the development of technology, the application of modern processes such as continuous pickling units has not only improved the efficiency and quality of pickling but also enhanced the environmental performance of the production process.

Cold Rolling Stage: The pickled strips are rolled at room temperature to further reduce their thickness to the target size. During this process, it is necessary to precisely control key parameters such as rolling force, speed, and reduction rate to ensure the dimensional accuracy and mechanical properties of the strips. There are various types of cold rolling mills, among which fully continuous cold rolling mills can realize continuous production, significantly improving production efficiency.

Degreasing Treatment: After cold rolling, it is necessary to remove the grease that may remain on the surface of the strips. Degreasing methods are divided into chemical and physical methods, among which chemical degreasing is the most commonly used, that is, removing grease through degreasing agents.

Annealing Process: Its main function is to eliminate the work hardening generated during the cold rolling process, soften the steel, and restore its plasticity and toughness. Annealing is carried out in protective gases such as hydrogen or nitrogen, which can further improve the quality and performance of the strips. Annealing methods include batch annealing and continuous annealing, etc. The specific selection depends on product requirements and production processes.

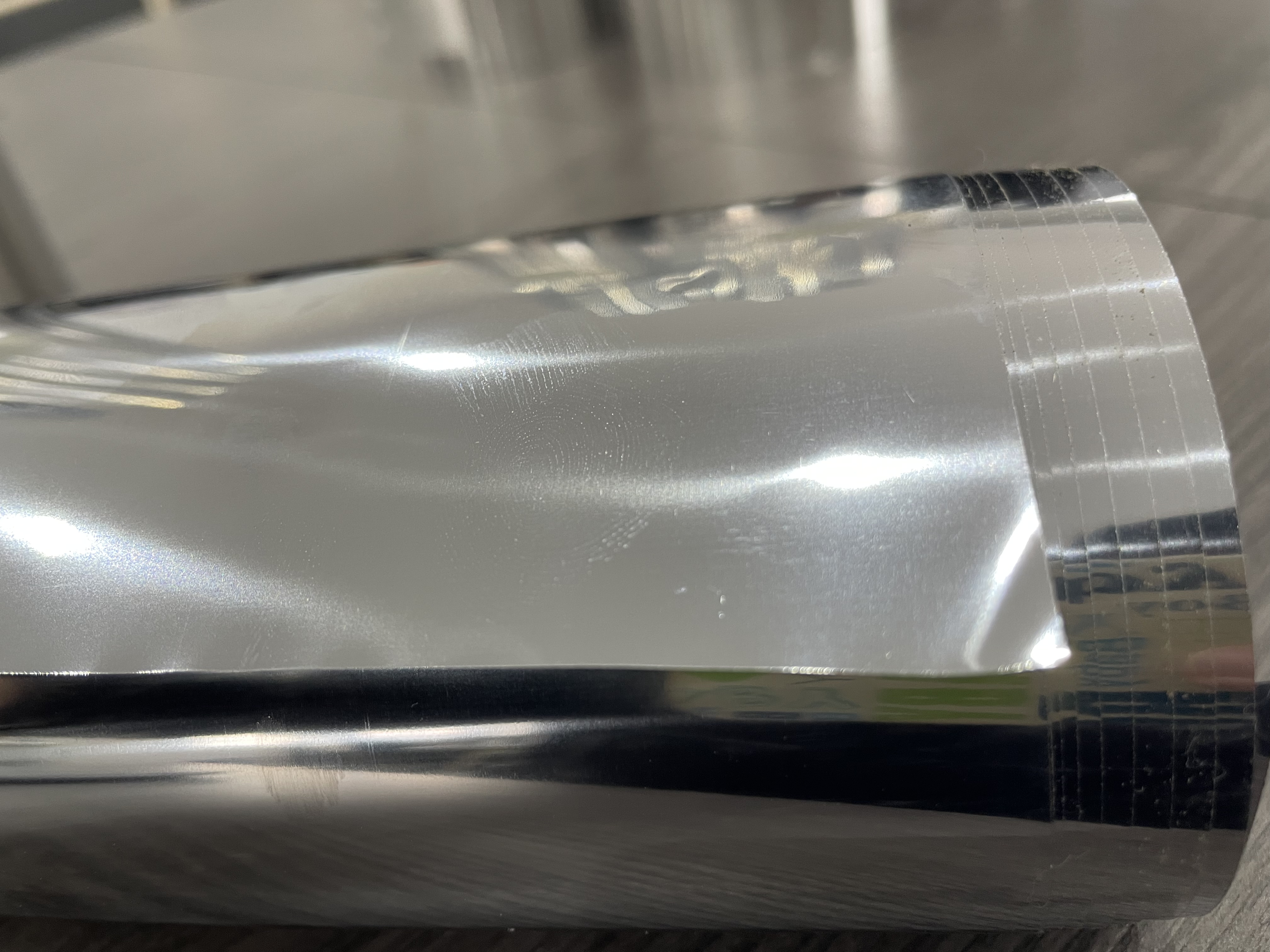

Temper Rolling and Shearing: The purpose of temper rolling is to obtain a flat and smooth strip surface and uniform thickness. It is necessary to strictly control parameters such as temper rolling force and speed to avoid adverse effects on the surface quality and mechanical properties of the strips. After temper rolling, the strips will be cross-cut or slit according to order requirements to become final products.

II. Innovation and Development of Cold-Rolled Thin Steel Sheet Production Technology

After years of research and improvement, the production technology of cold-rolled thin steel sheets has made significant progress in equipment technology upgrading and production process optimization, which are specifically reflected in the following aspects:

Equipment Technology Upgrading: The equipment level of modern cold rolling mills has been greatly improved, achieving a qualitative leap in precision, speed, and stability. For example, new cold rolling mills are equipped with advanced control systems, which can more accurately control the rolling process to ensure the dimensional accuracy and shape quality of the strips. In addition, their robust frame structure enables the rolling mills to withstand greater rolling forces, making it possible to roll thinner and wider strips.

The technology of annealing furnaces has also made significant progress. New batch annealing furnaces and continuous annealing furnaces have higher heating efficiency and more precise temperature control, which can better meet the annealing needs of different steel grades. At the same time, the energy-saving effect of these annealing furnaces is increasingly prominent, effectively reducing energy consumption.

Optimization of Production Processes: Traditional pickling methods are gradually being replaced by new technologies such as laser pickling and ultrasonic pickling. These technologies not only improve the efficiency and quality of pickling but also reduce the amount of acid used and environmental pollution. In addition, by optimizing rolling process parameters (such as reasonably adjusting rolling force, speed, reduction rate, etc.), the rolling efficiency and quality of the strips are improved, and the production cost is effectively reduced.

Application of Automation and Intelligentization: Automation technology has run through the entire production process of cold-rolled thin steel sheets (from billet loading to finished product packaging), reducing manual intervention and greatly improving production efficiency and the stability of product quality. The application of intelligent technology has realized real-time monitoring and optimization of the production process, which can timely detect and solve production problems, further improving efficiency and quality.

Product Quality and Diversified Development: With the increasing requirements of the market for the quality of cold-rolled thin steel sheets, manufacturers pay more attention to quality control. They use advanced testing equipment and technologies to conduct online testing and monitoring of various properties of the strips to ensure that products meet standards. At the same time, enterprises are committed to developing high-performance products, such as high-strength steel, corrosion-resistant steel, and high-value-added coated steel sheets, to meet the special needs of different fields.

Conclusion

The production process of cold-rolled thin steel sheets is a typical example of "exquisite craftsmanship" in industrial manufacturing. From the strict selection of raw materials to the precise control of each process, and then to the improvement of efficiency and quality brought by technological innovation, all reflect the technical strength of the modern iron and steel industry. With the continuous upgrading of market demand and the deepening of concepts such as environmental protection and intelligence, the production process of cold-rolled thin steel sheets will continue to be optimized, moving towards a more efficient, greener, and more precise direction. It will provide better material support for various industries and promote the continuous progress of the industrial field.

Baoshan District,

Shanghai, China.